General Questions

You must allow 24-48 hours for the start up chemicals to circulate. After that you are then able to vacuum the pool.

To calculate how many gallons of water are in your pool: Multiply pool size x average depth x 7.5 = approx. total gallons in pool Ex: Pool Size (12’x 24’) x Average Depth (3.5+6 /2 = 4.75) x 7.5 = 10,260 gallons.

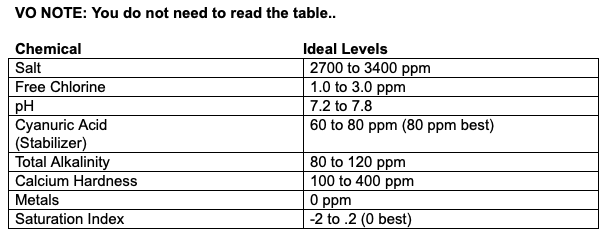

This table summarizes the levels that are recommended by the Association of Pool and Spa Professionals (APSP). The only requirements for the Aqua Rite are the salt level and stabilizer. It is important to maintain these levels in order to prevent corrosion or scaling and to ensure maximum enjoyment of your pool. Test your water periodically. Most pool stores can provide you with the chemicals and procedures to adjust the water chemistry. Be sure to tell the pool store if you are using an Aqua Rite chlorine generator.

If air is returning into the pool there might be a leak on the suction side of the pump. Check the following items that may be causing air to enter the system: The strainer cover and O-ring. Tighten if loose or replace gasket if damaged. Check the level of water in the pool – if it’s low, this may be causing water and air to mix into the skimmer. The skimmer weir may be stuck in the up position, causing water and air to mix in the skimmer. Check the drain plugs on the pump strainer housing. Check all of the threaded fittings for leaks from improper sealants or sealing procedures. Check glued fittings for bad glue joints. Check all valves for possible leaks. Valve stem O-rings are a common suction leak point. Check and ensure the pump is not cavitating. Check pump housing for cracks.

If there is earth or sand present in the pool it could be that the filter cartridges are torn or a crack in the manifold.

If there is water leaking underneath the pool pump it is likely that the pump seal needs to be replaced.

Filter Questions

DE is added through the skimmer with the pump running. Each filter has a different requirement of DE. At initial start up or after a thorough cleaning, the filter will need to be pre-coated with DE. The filter label will state the amount of DE required. Start the pump and once the pump is fully primed, measure the DE using a DE scoop, part # EC10SC. Slowly add the DE into the skimmer. The pump will draw in the DE and send it into the filter, where it coats the grids or Flex tubes. Once all the DE is added, take a reading of the filter’s pressure gauge. This is the clean starting pressure of the filter. When the pressure rises 8-10 PSI above the starting pressure, it is time to backwash or clean the filter. After the filter is backwashed or thoroughly cleaned, by taking it apart and hosing it out, you will need to pre-coat the filter again with the entire amount of DE stated on the filter label.

The following are the steps to cleaning a cartridge filter:

- Make sure the pool pump is off

- Release all the air from the air relief valve located at the top of the filer

- Loosen the band around the filter

- Remove the band and the filter lid

- Remove the cartridges

- Attach a high-pressure nozzle to a garden hose

- Clean cartridges by hosing them down with water (do not use a power washer)

- Place cartridges back into the filter

- Check that the O Ring along the top of the filter base is tightly snug before placing the lid back on

- If the lid is not snug or won’t go on, replace the O Ring

- Attach the band back on and tighten, make sure there are no gaps

For a 4820 DE Filter: 4 to 5 pounds of DE are to be added after you backwash your filter

For a 6020 DE Filter: 5 to 6 pounds of DE are to be added after you backwash your filter

D.E. filters filter the water down to 1-3 microns, every time the water passes through the filter. Maintain a balanced clear pool and this will reduce incidents of rapid pressure rise. One possibility for a rise is that the filter grids or Flex tubes are clogged with minerals or oils. You should clean your grids once a year, or season, with a degreaser and if needed an acid bath. Minerals and oils embed themselves in the fabric of the filter and reduce the available surface area used for filtering. If too little DE is added during pre-coat, debris and particles will embed in the fabric. Cleaning with a high-pressure hose, NOT A POWER WASHER, may be needed to remove the grids. If cleaning does not work, then replacement is the only option

A dirty filter can reduce water flow to your pool. When the filter pressure rises 8-10 PSI over the clean starting pressure, it is time to backwash or clean the filter. Another possibility is algae in the pool- it may be clogging the filter, keeping the pressure high. The filter cannot kill algae. If the problem is still not solved, you may have a blocked or plugged return line.

The valve seat gasket inside of the valve may have become worn or loose. If this is the case, you will need to replace the gasket. With the pump off, remove the cover screws of the valve. Be sure to mark the top and bottom of the valve with a marking pen. It’s very important that you do not change the location of the cover when re-assembling. Some newer valves will have a flat spot alongside one of the cover screws. When re-assembling, align the flat spots. Gently remove the old gasket and glue, ensuring the channels are clean and clear. Use 3M adhesive or crazy glue. Lay a bead of adhesive into the channel where the gasket sits. Place the flat side of the gasket into the channel. Apply pressure to firmly seat the gasket and let dry for 24 hours.

There are only a handful of reasons DE is leaking into the pool. They vary depending on which DE filter you have. If you own a Vertical Grid, check to see if too much DE was added. There might be a tear in the fabric of the grid, or a crack in the top manifold. Or the problem could be a bad o-ring on the standpipe.

Pump Questions

There are several possible reasons why your pump won’t fill with water:Check for any air leaks on the suction side of the pump. Also make sure the suction line is free of obstructions.

Check to make sure the impeller is still attached to the shaft of the motor. If the impeller has broken off, it will need to be replaced.

If the pump is installed a distance from the pool or is elevated above the normal deck level, the time needed to prime the pump could be longer. For elevated installations, a check valve may be needed on the suction line to allow for easier priming.

Hayward in-ground pumps are self-priming centrifugal pumps. These pumps have a vacuum chamber, commonly known as a pump housing. The pump housing must be filled with water in order to create a vacuum, resulting in the pump drawing the water out of your pool or spa. The pump housing will remain full of water while the pump is on, and will remain full or partially full when the pump is shut off. When powered on, the motor will begin to rotate. 2-speed pumps will power on a pre-selected speed or with some controllers, it will cycle at high before changing to the lower speed. The motor spins the pump impeller, located inside the pump volute. While the motor is rotating, the tips of the impeller are hydraulically sealed inside the pump diffuser, which is responsible for self-priming. Self-priming can only occur if the pump has a diffuser—all inground Hayward pumps have an internal diffuser. It helps to eliminate any air approaching into the pump housing from the suction piping. As all the air is removed from the system, you will notice bubbles returning to the pool through the return fittings. A full prime occurs when the bubbles stop returning to the pool and the pump basket is full of water. The filter pressure will rise as the pump reaches full prime. The actual gallons per minute (GPM) vary with the type of pump, horsepower, pipe size, distance from pool and other restrictions within the plumbing system. Hayward self-priming pumps are very dependable and simple in design. They require a sufficient supply of water from the pool or spa, and no air in the suction lines. Air could come from a loose strainer cover, a leak in any valve, or a pinhole in any suction line.

Heater Questions

The “LP” light comes on when the outside temperature is below 50 degrees.

The most common cause of a heater that cycles on and off could be inadequate water flow due to a dirty filter or closed valve. (See information on How to Backwash a DE Filter or Clean a Cartridge Filter) If you backwash your DE Filter or clean your Cartridge Filter and the heater continues to cycle on and off the culprit could be reversed water connections or a water pressure switch out of adjustment.

Most likely your heater is dirty. Clean your cartridge filter or backwash your DE Filter, follow steps in the FAQ.

Most likely your heat pump is leaking water because of condensation. To ensure that condensation is the cause of the leak, take a test strip, and test the leaking water for chlorine. If the test strip shows no chlorine present then the leaking water is condensation from the pump and there is no need to be alarmed or do anything more.

Salt Generator Questions

If your salt generator reading is displaying a higher than recommended salt reading, try to recalibrate your average salt reading, to do this:

- Turn the system Off and back to Auto

- Push the Diagnostic button until Instant Salt appears on display (wait until it stabilizes then proceed to the next step)

- While showing Instant Salt, flip main toggle switch from Auto, up to Super Chlorinate then back to Auto

If the ‘Inspect Cell’ light flashes by itself, it is an early indication that the salt generator needs a manual reset. Each cell is equipped with 500 operational hours and requires a manual reset once it expires. To reset the cell, hold down the ‘Diagnostic’ button for 3-5 seconds.

If both the “Check Salt” and the “Inspect Cell” lights stay on it most likely means that no chlorine is being produced at this time, and your salt level fell below 2300 ppm. Both lights will also stay on if the control is set to the wrong turbo cell type, or if the cell is unplugged. Check the following: Independently verify the salt levels in your swimming pool by utilizing your at home testing kit. Once your water has been tested, add salt to your pool to bring your levels back to the recommended 2800 – 3200 ppm. If your independent testing shows your salt levels are correct, but your system is showing something different, you may need to recalibrate your Aqua Rite unit. Inspect and clean cell, if necessary. Verify if the control is set to the correct turbo cell.

The ‘High Salt’ light indicates that there is a higher salt level than recommended. The ‘High Salt’ light will stay on for several reasons including: cell amperage is above the maximum limit, the control is set to the wrong turbo cell, or most commonly there is too much salt in your pool. The LCD display will read “HI”. Check the following: You can utilize your at home testing kit to verify the salt levels in your swimming pool. Once your water has been tested, if the reading is too high, reduce the levels of salt in your pool to bring your levels back to the recommended 3200 ppm. Verify if the control is set to the correct turbo cell. Verify cell amperage to ensure it is not above the maximum limit for your model. Check below for the maximum current amps before the unit shuts down.

The ‘No Flow’ light indicates that the flow switch is not detecting sufficient water passing through. Check the following: Cleaning the cell or the filter (See How to Backwash a DE Filter or Clean a Cartridge Filter) Replace the flow sensor.

When both the “Check Salt” and “Inspect Cell” lights flash together, it is most likely an indicator that your salt level is below 2700 ppm. Keep in mind, your ideal salt level should be between 2800 ppm – 3200 ppm. Your AquaRite system may be working efficiently and your pool may be clear at the moment, but in a week or so, it may not be the case anymore.

Check the following: Independently verify the salt levels in your swimming pool utilizing your at home testing kit. Once your water has been tested, add salt to your pool to bring your levels back to the recommended 3200 ppm. Inspect and clean cell if necessary.